High-Quality Finished Cable & Wire Products From the Experts in Cable Design:

Don’t let electrical problems and wiring issues compromise your product’s quality! Our quality assurance department monitors our cable and wire harness manufacturing process every step of the way, from order to delivery. Each cable is thoroughly tested prior to shipment and is sent with its required certified documentation.

We work to assist your business by guiding you through the transitioning process from ‘made in-house’ components and sub-assemblies, to fully-documented cable assemblies and harnesses, made on automated equipment within a tightly-controlled process. Our electrical design and engineering teams guide your associates in designing the most-efficient and lowest-cost cable solutions for your end product; using popular wire, cable, and connective components meant to save you money. We can quote from your existing prints or via a sample, and will provide engineering documentation when required.

We are very proud of our personalized service, attention to detail, and innovative approach. Paradise Cable Industries is focused on becoming your greatest source for all cable, harness, and wire assembly needs! Our custom and stock products include:

Cables & Harnesses

Cable Assemblies – We make a wide variety of custom cable assemblies to service various industry segments. We have tooling for many older cable components, and are happy to quote in volumes that are applicable for cables nearing the end of their service life or that are transitioning from production to service. We can provide custom jacketed cables with a mix of wire gages and colors to your specification when your volumes allow for minimum factory runs. We will obtain and store your custom cable, building and shipping assemblies to service your monthly requirements. We encourage you to challenge us with your non-standard cable designs

Long Cables – Whether you are looking for long cables for installing or connecting purposes, we have an extensive variety. We make custom cables in longer lengths (i.e. 250 feet) by pulling individual strands of wire per customer specification. Our long cables come in the exact size that you are looking for.

Harness Assemblies

We make a number of small harness assemblies with series wire breakouts using state-of-the-art splice-band equipment. We also make larger harness assemblies using harness boards and a variety of harness cover materials. We follow all geometric and electrical requirements, ensuring your satisfaction every time.

Molded Products

Molded Cables – At Paradise Cable Industries, we supply tooling and molding services to create plastic or rubber over-connectors to improve appearance, embed customer logos, and provide strain relief at the cable exit.

Test Probe Cables- May use molded connectors for high use durability and can be terminated in a variety of test probe tips or connector clamps.

Embedded Components

Embedded components – We embed series resistors and other axial components using splice-banding equipment. Our test equipment checks for these devices. Customers send us small electronic modules for wire termination and other custom work.

Electronic Assemblys

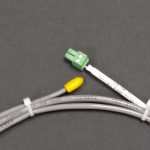

Temperature Sensors – We embed a variety of temperature sensing devices into quick connector or ring terminals using thermally conductive potting material. Cables are included per customer specification.

Specialty Products – We assemble a variety of electrical equipment sub assemblies that include chassis assembly wired connectors, fuse holders, and power entry components.

Custom Printed Labels

We print labels in house to your specification, which lowers cost and increases flexibility. We can date code or number code manufacturing lots. We can print on many types of shrink tubing, allowing us to combine insulation and labeling onto one component.